Fellfoot Forward Landscape Partnership Scheme

Future Fair case study – Barugh Cottage Produce

Future Fair project manager, Roe Baker, talked to smallholder, Nicola Reed, about Barugh Cottage Produce and the support received through the Fellfoot Forward Landscape Partnership Scheme.

Nicola’s smallholding consists of three plots of land close to her home which she and her family manage in as low input a way as possible, with a conscious effort to keep emissions down. Sustainability is a key factor in how she manages the land. Nicola has been keeping the smallholding since 2013 and has always kept livestock and used working horses to till the land.

The Fellfoot Forward Environment Grant panel awarded Nicola just under £2,000 to enrich the Fellfoot Forward landscape by creating a new hedge that connects to the existing road verge-hedge habitat network. The benefits, over ten years, would be additional wildlife hedge habitat, additional shelter and browse for livestock. The estimate of carbon sequestered – tbc.

The Fellfoot Forward Environment Grant was awarded to Nicola’s plot at Parkhead where she keeps stock. The grant supported the planting of a hedgerow along the track adjoining her hayfield. The environment grant stipulates that planting must be for a minimum of ten years but Nicola sees it as a permanent feature which will provide shelter, habitat, and, ultimately, support carbon sequestration and reduce soil erosion: “We know the hedge won’t impact on our profitability, we planted it because it will offer shelter to our stock and is beneficial to the welfare of the land”.

Nicola also keeps sheep for part of the year on a plot of land nearby, which is a conservation grazing site managed by the Kirkoswald Environmental Group, and she keeps pigs, sheep, goats for their milk and meat, chickens, horses and grows potatoes.

Roe asked Nicola what drives her – because running a smallholding can be an intense and hard lifestyle choice. Nicola replied: “I want to produce high welfare food. I want to know where and how food has been produced. I want to provide the local community with great quality produce and to be able to do it with pride. It’s challenging to develop a viable business because it takes a while to build things up, we are by our nature very ‘out of the way,’ so we’re reliant on building a local customer base”.

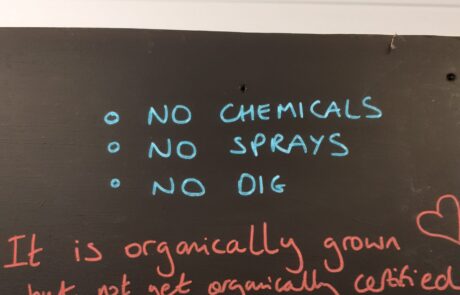

When asked what impact Nicola saw her work having on the local community, she said: “We sell produce in the Farm shop from other local producers and businesses. The vegetables and flowers come from a producer in a neighbouring village who is developing her plot organically, without pesticides and we stock supplies from Little Salkeld Water Mill, produce from Wild and Fruitful and bread, flour and oatcakes from Warwick Mill amongst others”.

Nicola spoke about her carbon journey and what barriers she sees to reducing her emissions more: “This is the first grant I’ve received. We’re too small for a stewardship scheme, we’re only viable because we combine the smallholding with our other household incomes. It’s challenging to have to cost and justify everything you do against upfront investment and viability. Being part of the Fellfoot Forward scheme has been really useful in keeping sustainability at the forefront of my mind and advice from the scheme managers helps us to plan what to do next.

Although we’re not certified organic, we take our impact on the environment and the climate very seriously and wherever possible we source our suppliers sustainably and consider how to use by products and waste. All our animal feed is British grown, bran and malt culms are a by-product of flour milling and the spent barley grains used in whiskey production. Sugar beet is a by-product of British sugar production. We also use a few high protein field beans and the forage crop lucerne, along with a small amount of supplemental seaweed, all non-GM and UK grown/sourced.

I choose to buy timber for fencing from a local agricultural merchant who is our local supplier. This comes down to convenience, availability and cost. If we work with local contractors, then it often comes down to where the contractor gets his supplies. In the end it comes down to cost and what we can afford to do”.

Nicola is keen to join the Fellfoot Forward farm carbon pilot and calculate her smallholding emissions. The farm carbon pilot is being led by the Cumbria Farmer Network, a key partner in the Fellfoot Forward scheme, and will start in Autumn 2021.

Installing renewable energy in the form of solar photovoltaics (PV) could be a way to reduce energy used from the farm shop freezers. Because the Barugh Cottage smallholding is in Eden, we were able to signpost Nicola to the Cumbria Business Environmental Network (CBEN) for support via the Greening Eden Project. Greening Eden is a project funded by Eden District Council, managed and delivered by the CBEN Partnership. The project will allow businesses across Eden to measure their greenhouse gas emissions, identify opportunities for reduction, and support EDC’s ambitions for a low-carbon, environmentally sustainable Eden and Cumbria.

Philip Wanless from CBEN visited the smallholding and thinks a number of things could be done, relatively easily, to improve the smallholding’s carbon emissions while benefiting the business profitability:

- Solar PV for the farm shop roof should be able to offset the energy use from the entire shop and potentially expand the shop in the future. (Solar thermal panels aren’t cheap but there’s always a second hand supply.)

- Captured rainwater run-off from garage roofs utilised to water crops would result in a small carbon saving for very little cost

- Create a ‘hot box’ manure heap and utilise the escaping heat to warm raised beds for growing. Cover the hot box with a polytunnel or greenhouse to capture any heat emissions and maximise use.

- Adding solar thermal panels to the roof of the structure covering the hotbox could potentially heat water to around fifty to sixty degrees. Before filling the compost bin, the pipes from the solar thermal panels could be run across the floor of the compost area with a pump to move the water across the floor of the bin, then back through the solar collector. That way the system would be constantly heating the compost, moving from a hot box to a super-hot bin. There may even be potential to claim a Renewable Heat Incentive (RHI) if it can be classed as an industrial purpose for the heat. (Implementing this system would not be saving carbon directly, but it would provide an extended growing season or even generate a winter season thereby reducing Scope 3 supply chain emissions.)

You can read more about Barugh Cottage products and camping, and sign up to Nicola’s blog here. Barugh Cottage Farm Shop, Ainstable, Carlisle CA4 9RQ